E-Roll

Features of E-Roll for test machine(Under φ30).

Features of E-Roll for test machine(Under φ30).

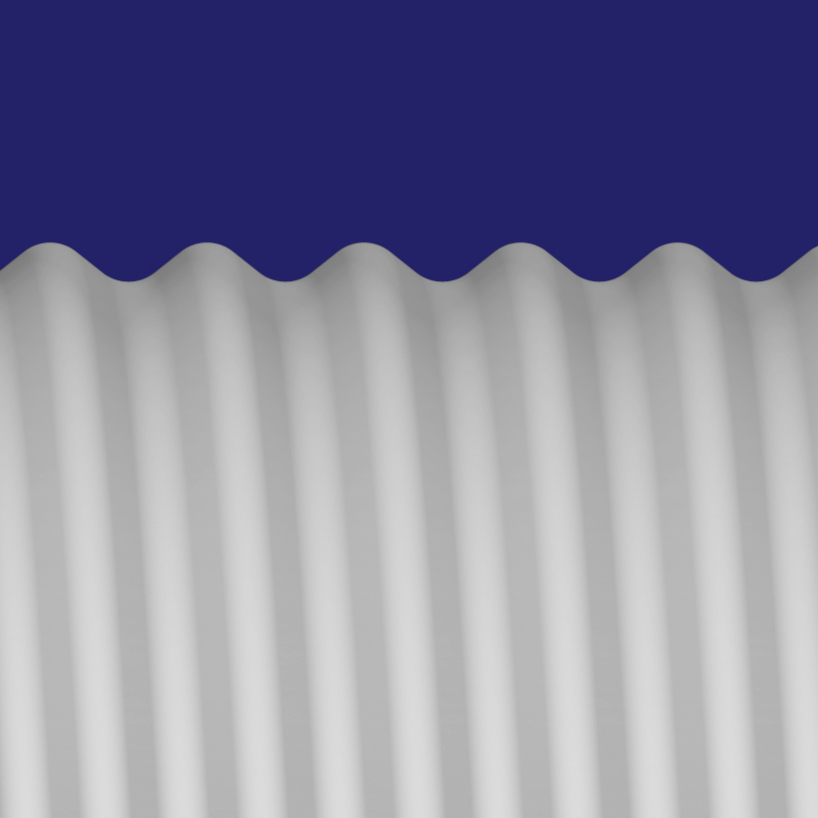

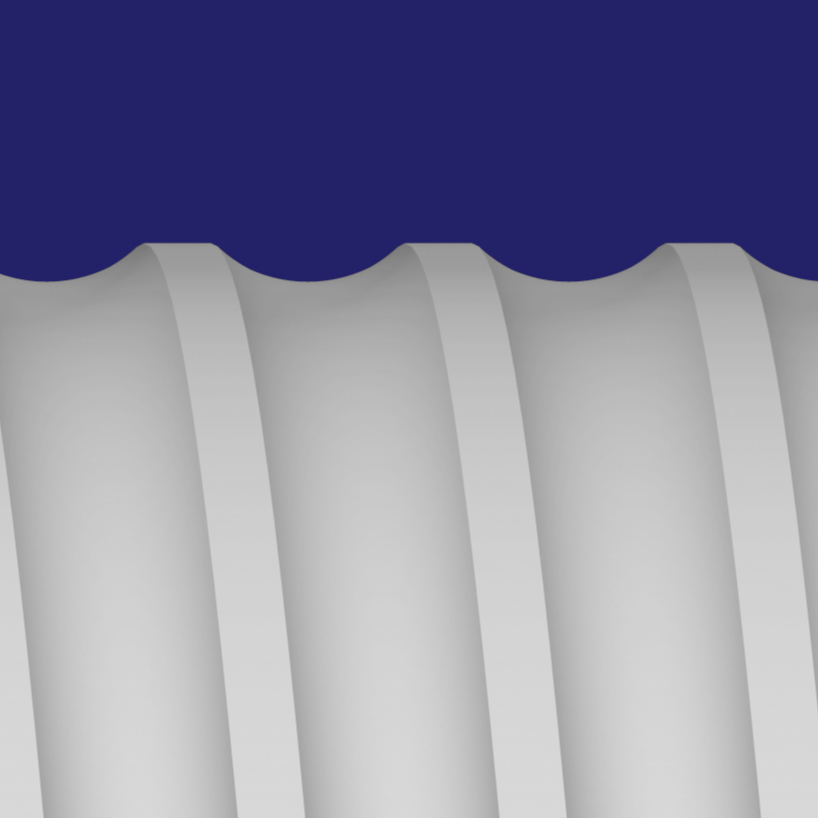

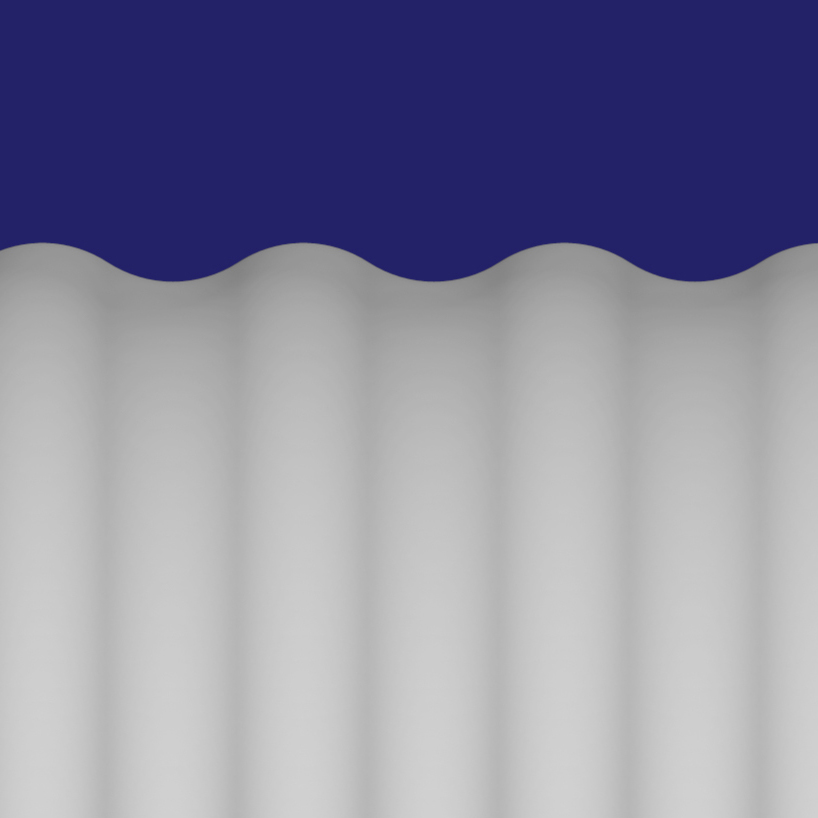

A wide variety of groove shapes are available.

Surface treatment

|

SUSThe material of E-Roll(Under φ31mm) Use SUS300 series stainless steels(austenitic stainless steel) with good corrosion resistance. |

|---|---|

|

HCr.HCr layer is relatively hard and has excellent abrasion resistance, and corrosion resistance. |

|

DLCDLC layer is extremely hard and also low in coefficient of friction. In addition, DLC has a higher hydrophilic compared to SUS and HCr plate. |

|

SUSThe material of E-Roll(Under φ31mm) Use SUS300 series stainless steels(austenitic stainless steel) with good corrosion resistance. |

|---|

|

HCr.HCr layer is relatively hard and has excellent abrasion resistance, and corrosion resistance. |

|---|

|

DLCDLC layer is extremely hard and also low in coefficient of friction. In addition, DLC has a higher hydrophilic compared to SUS and HCr plate. |

|---|

Delivery time

Others·Support

CATALOG / TECHNICAL DATA

CATALOG

TECHNICAL DATA

© OSG SYSTEM PRODUCTS Co., Ltd.