D-Bar

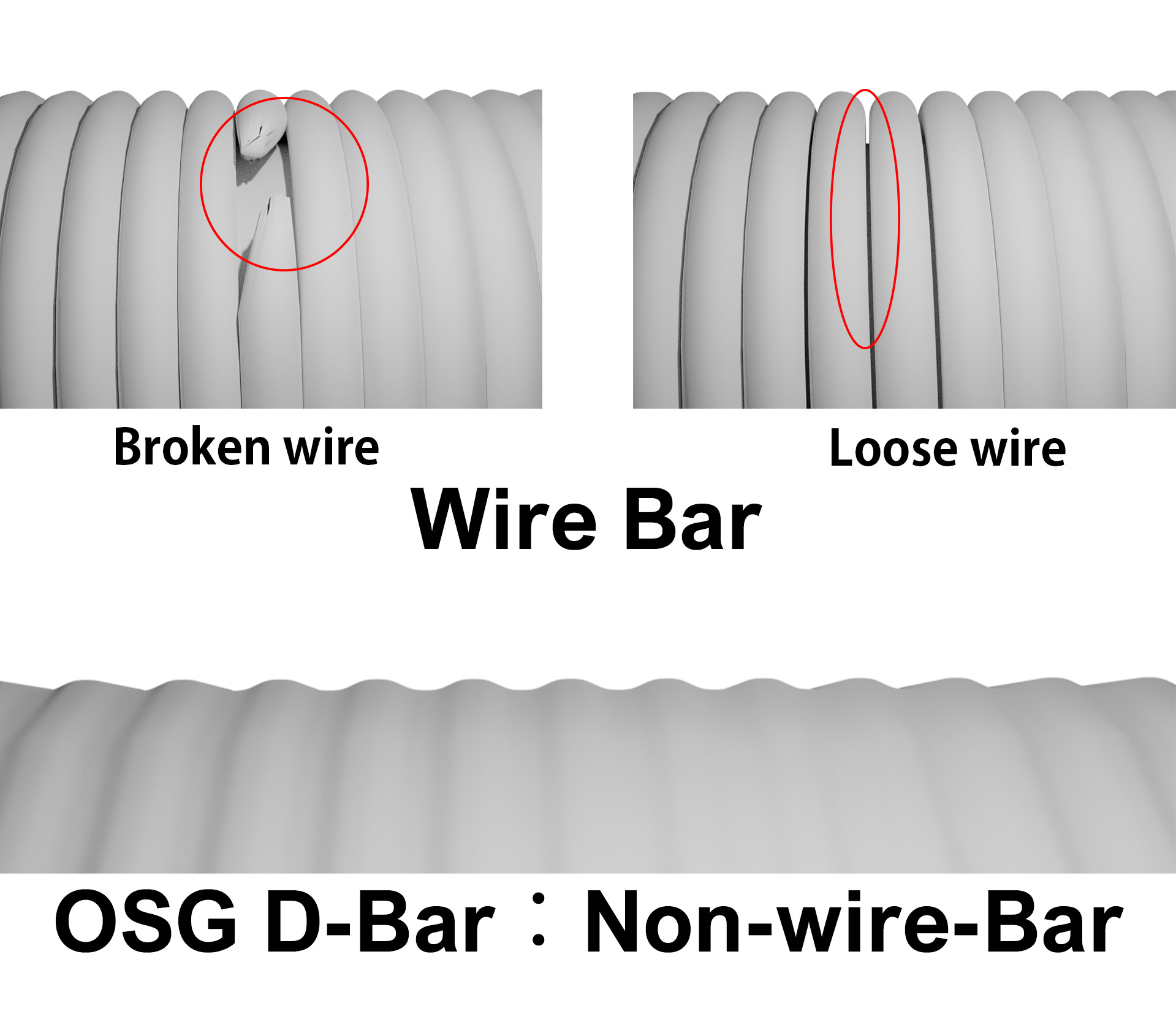

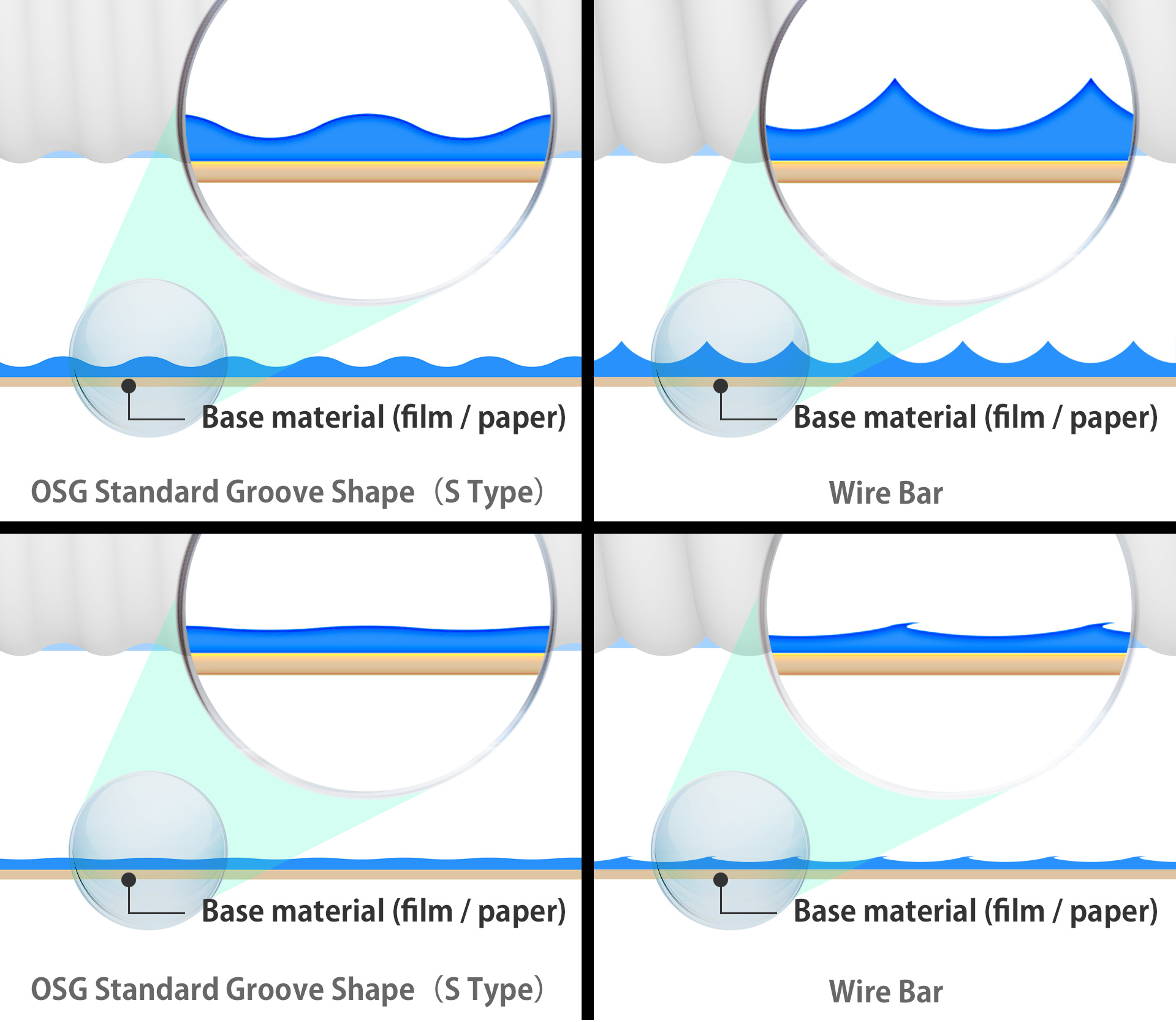

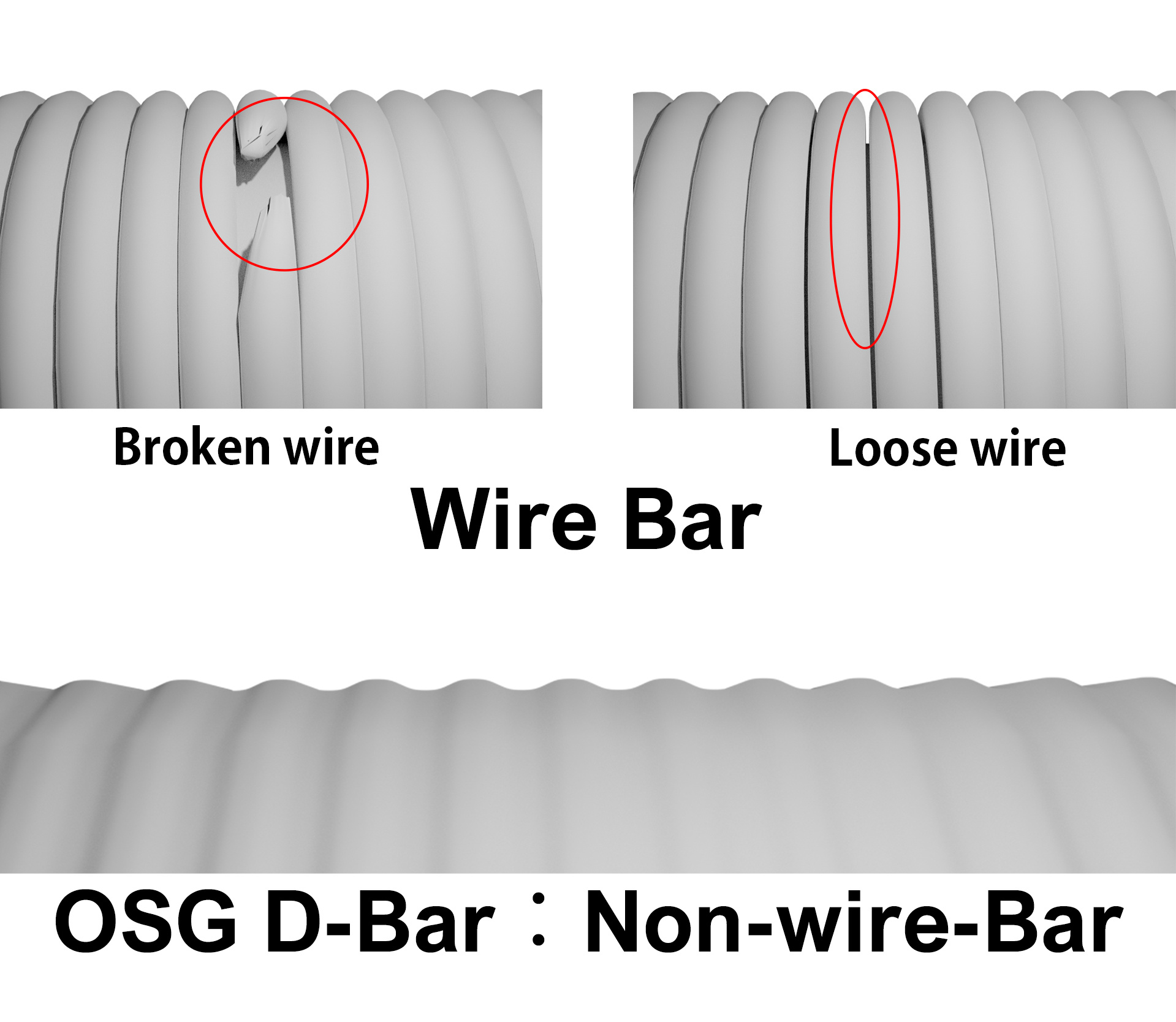

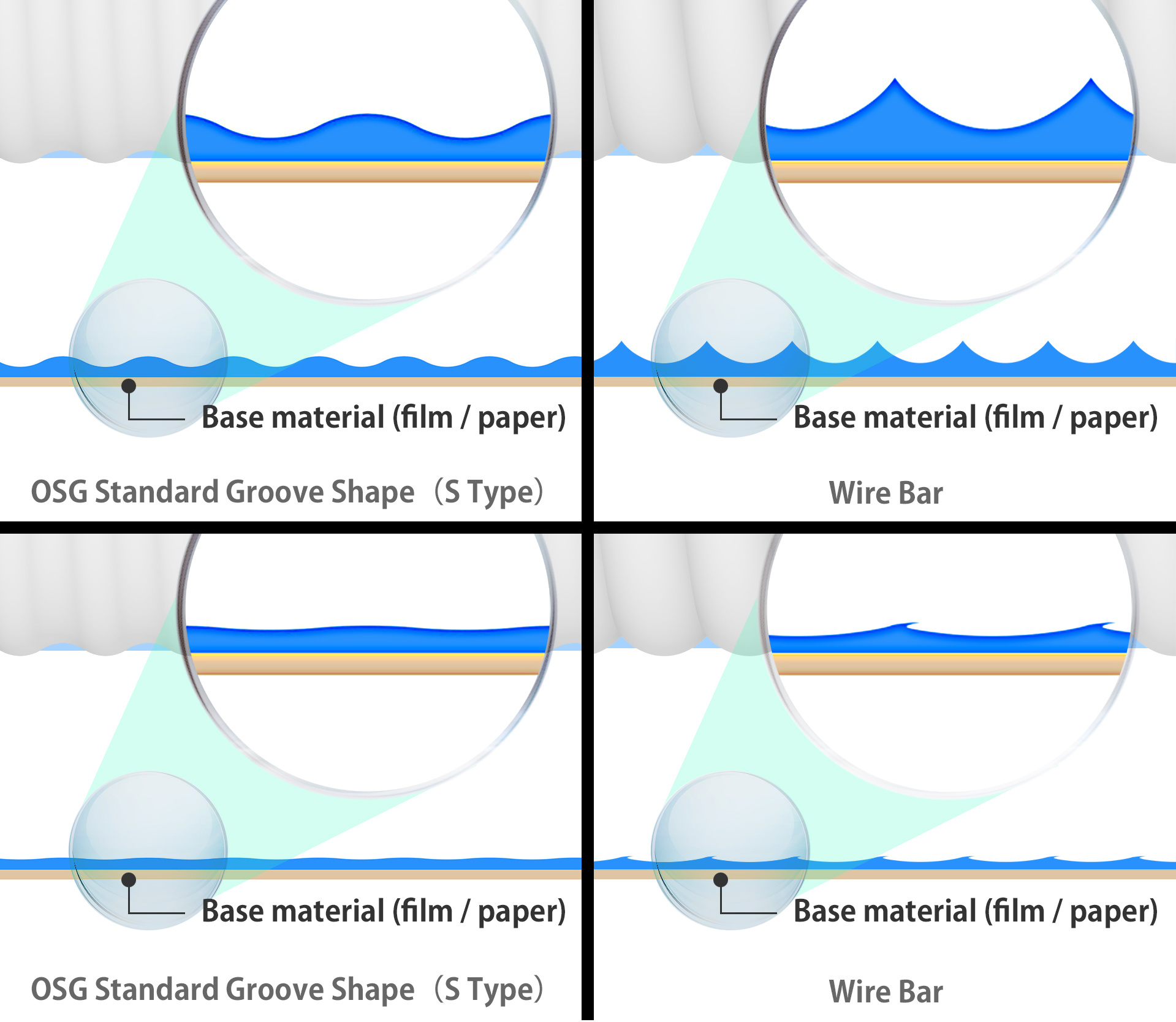

Expect effect of Wireless bar

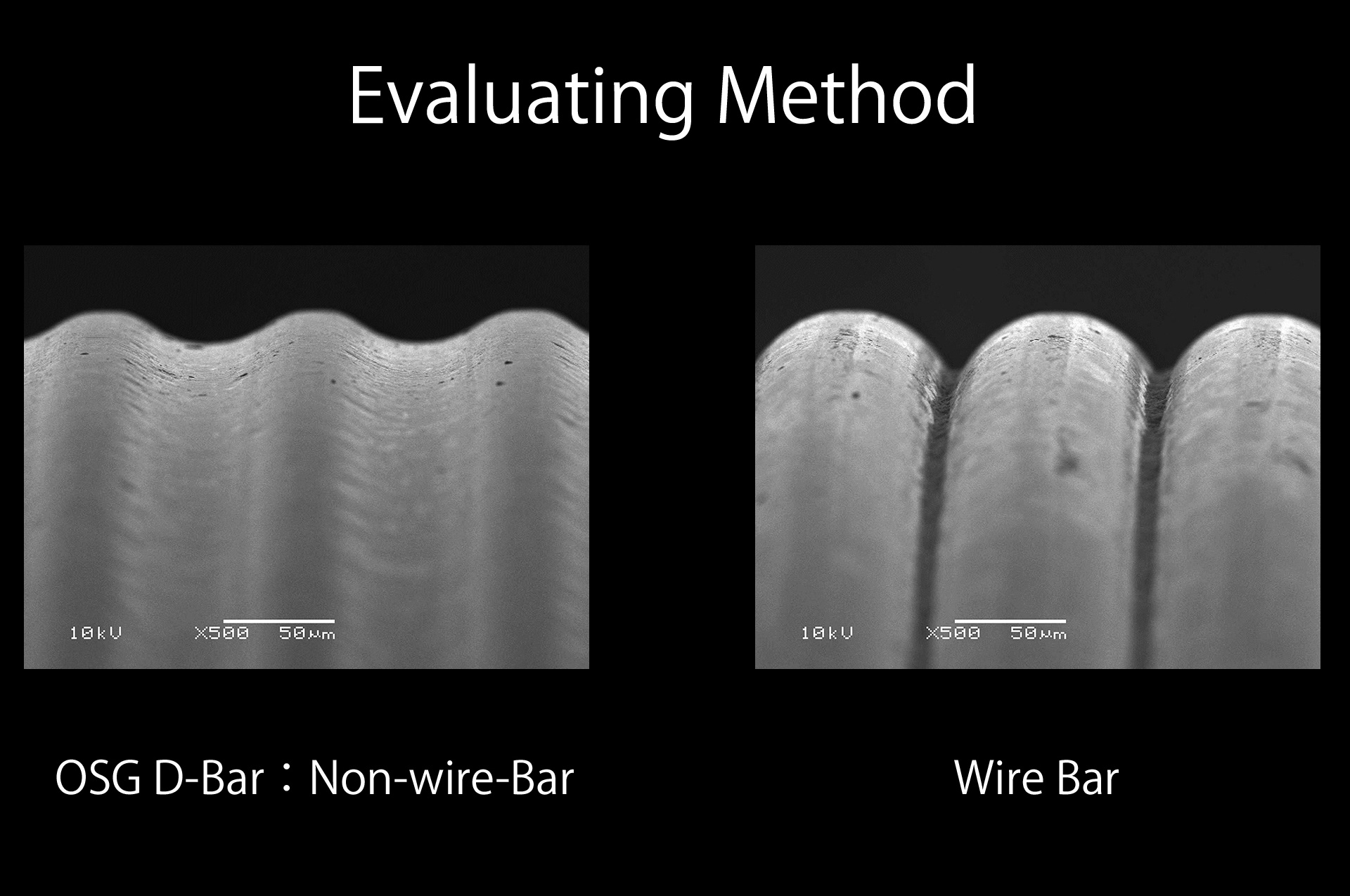

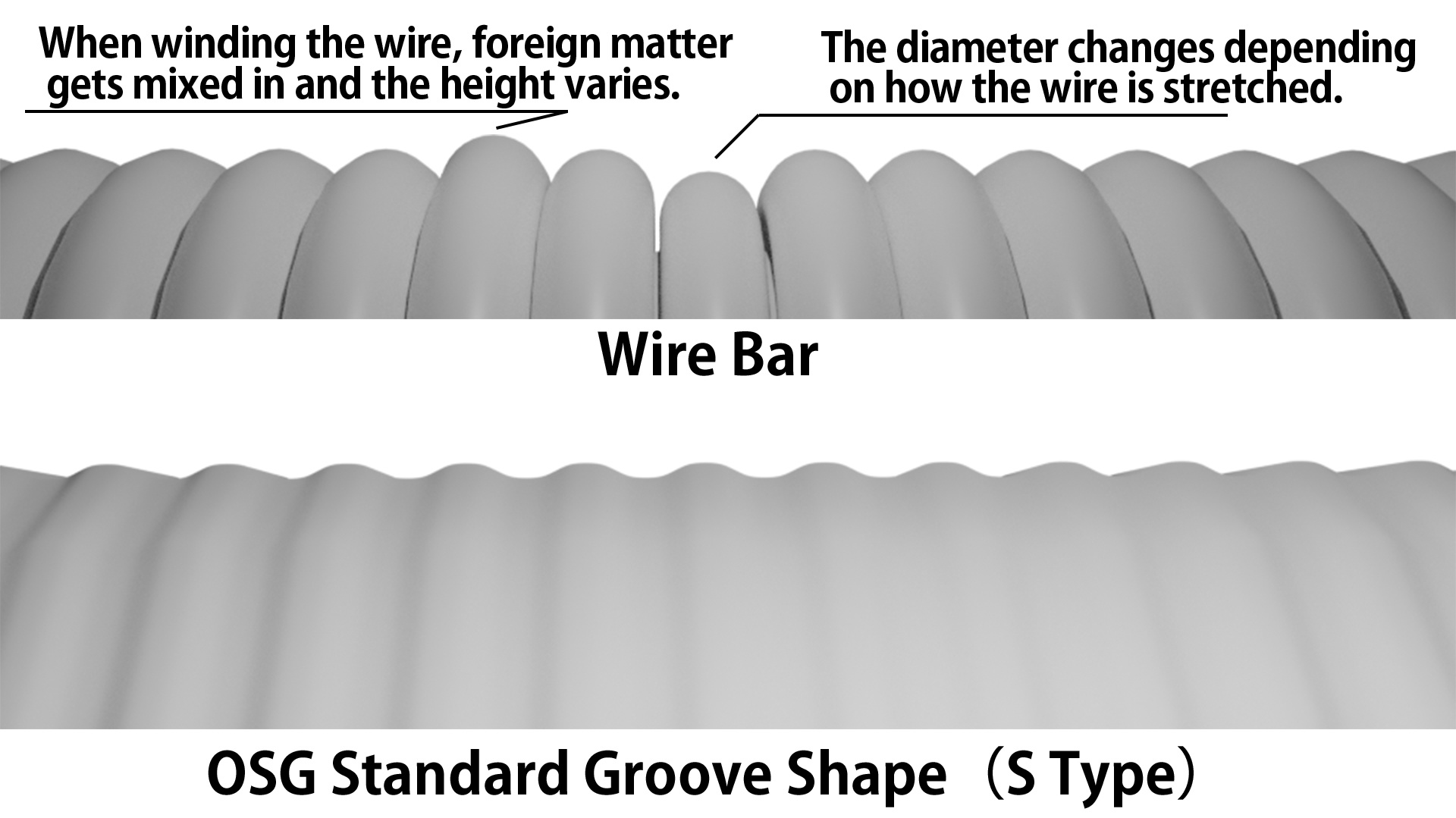

Features of Wireless Bar

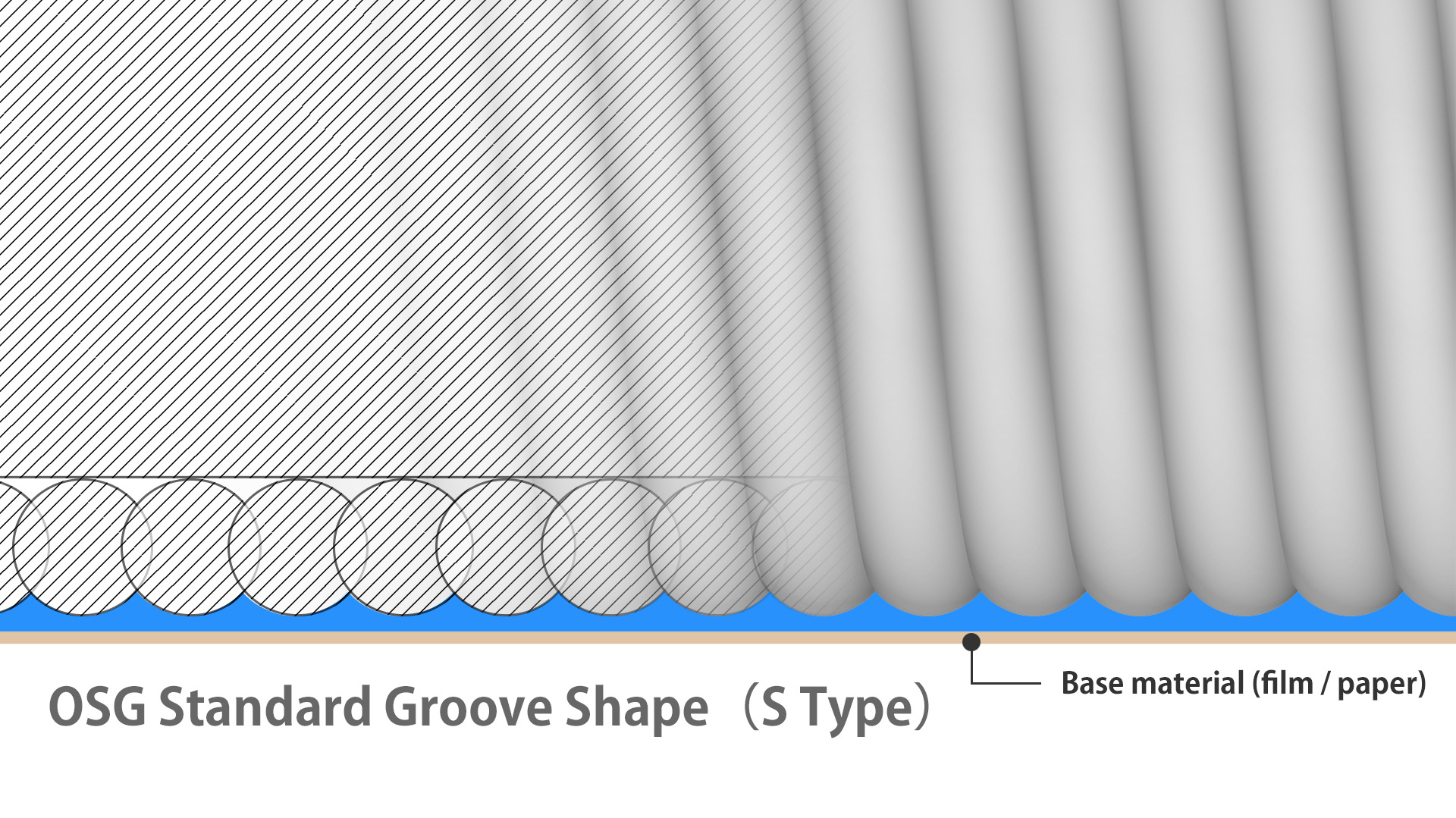

Features of solid design

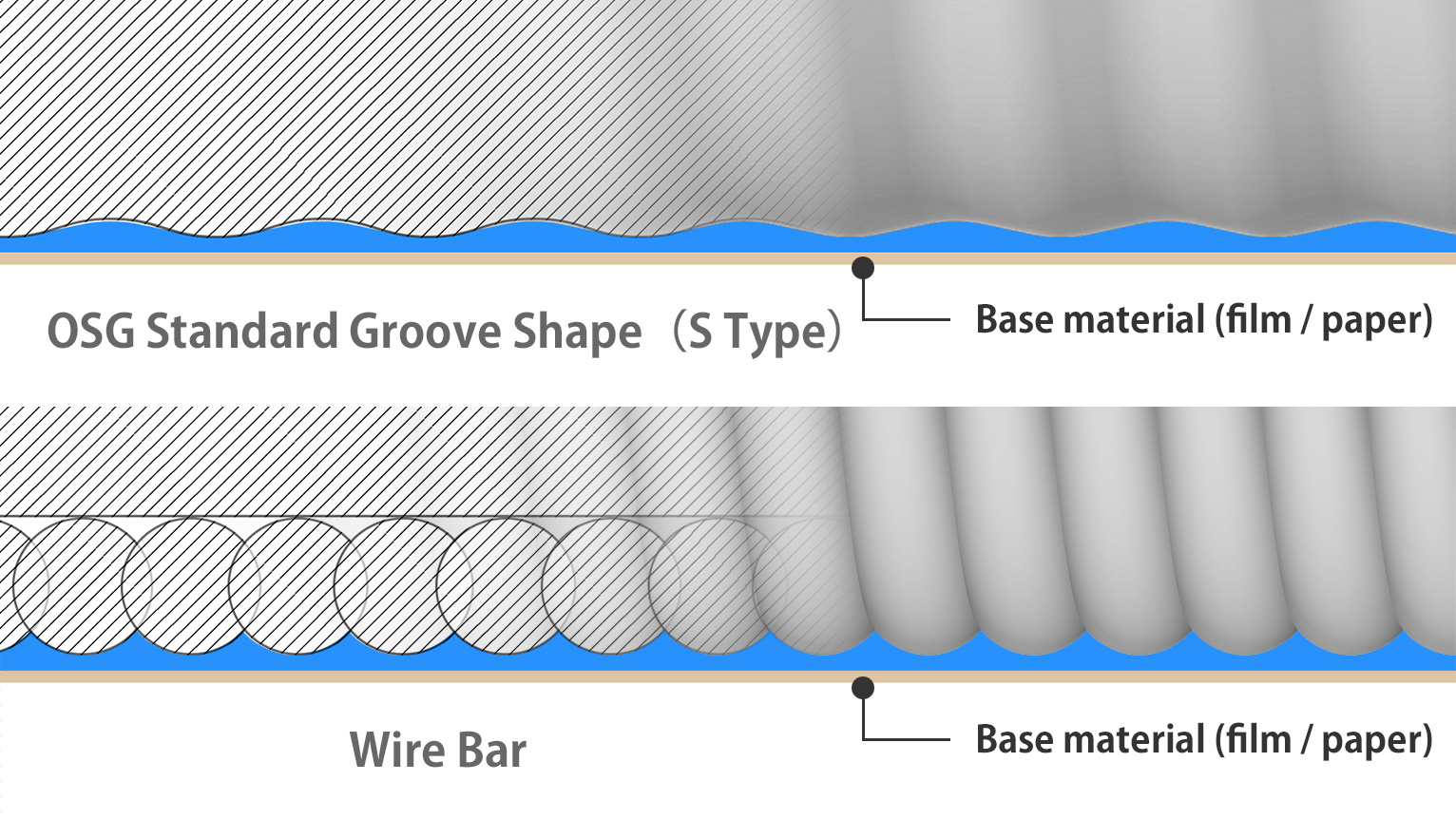

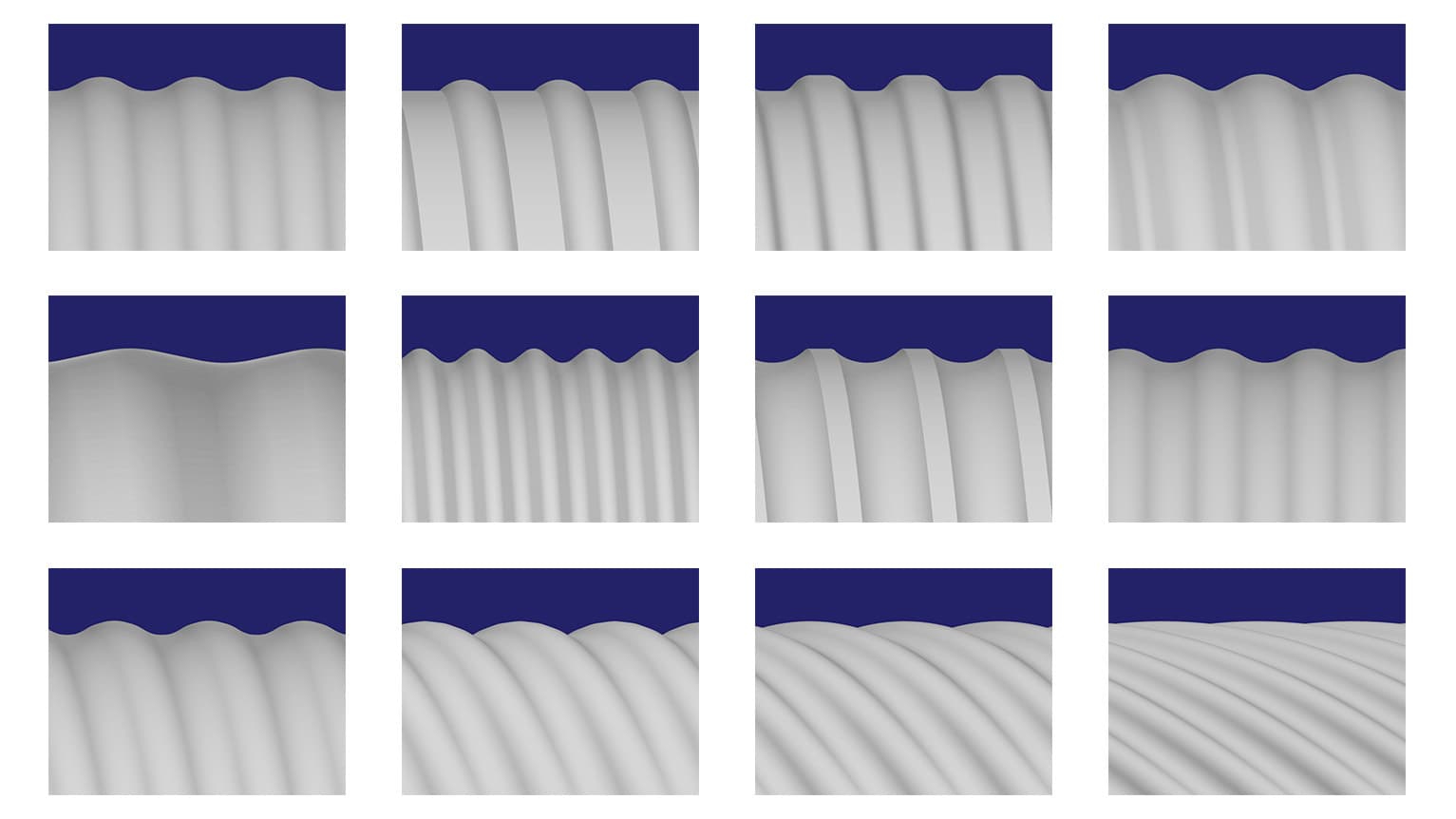

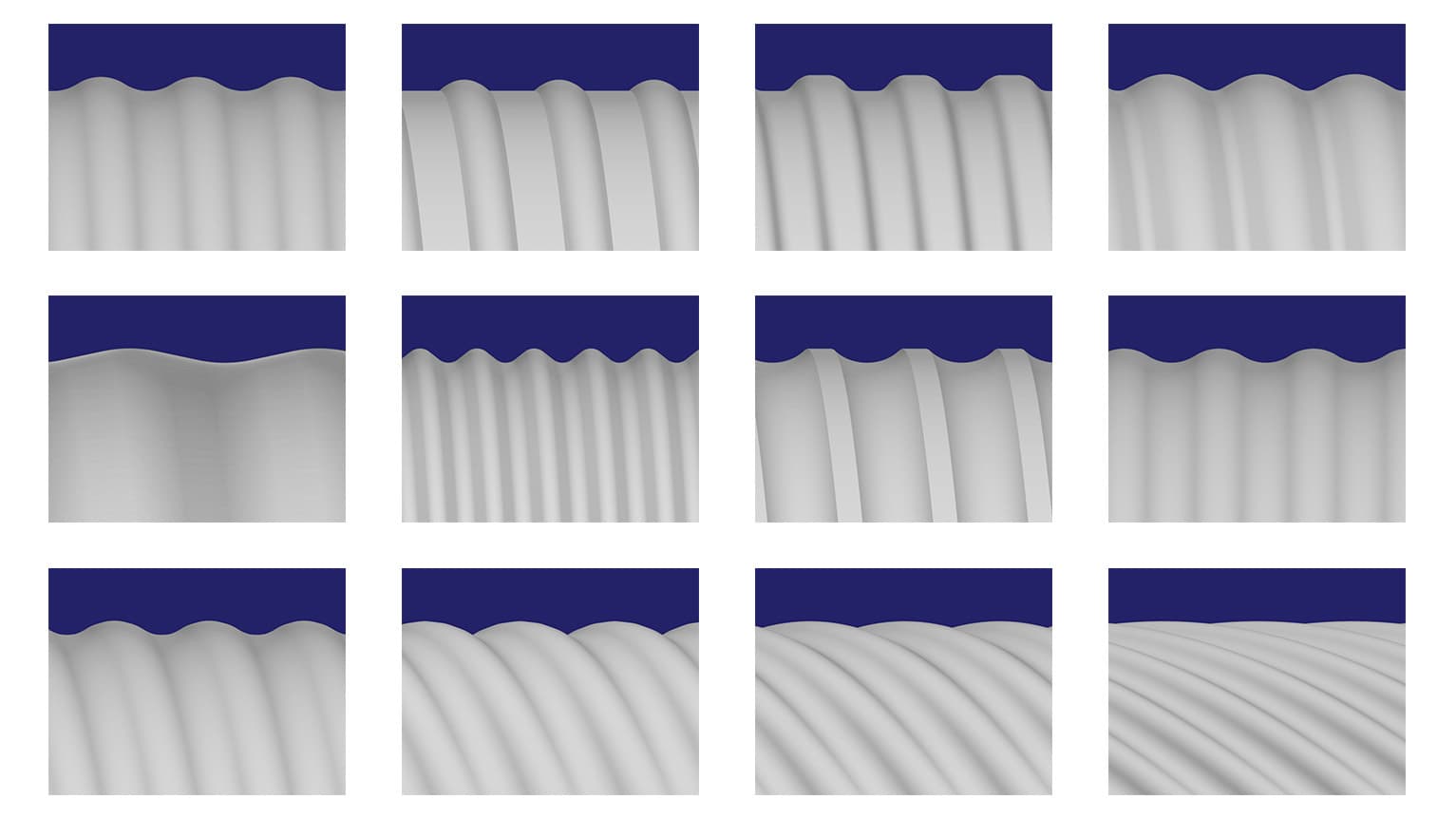

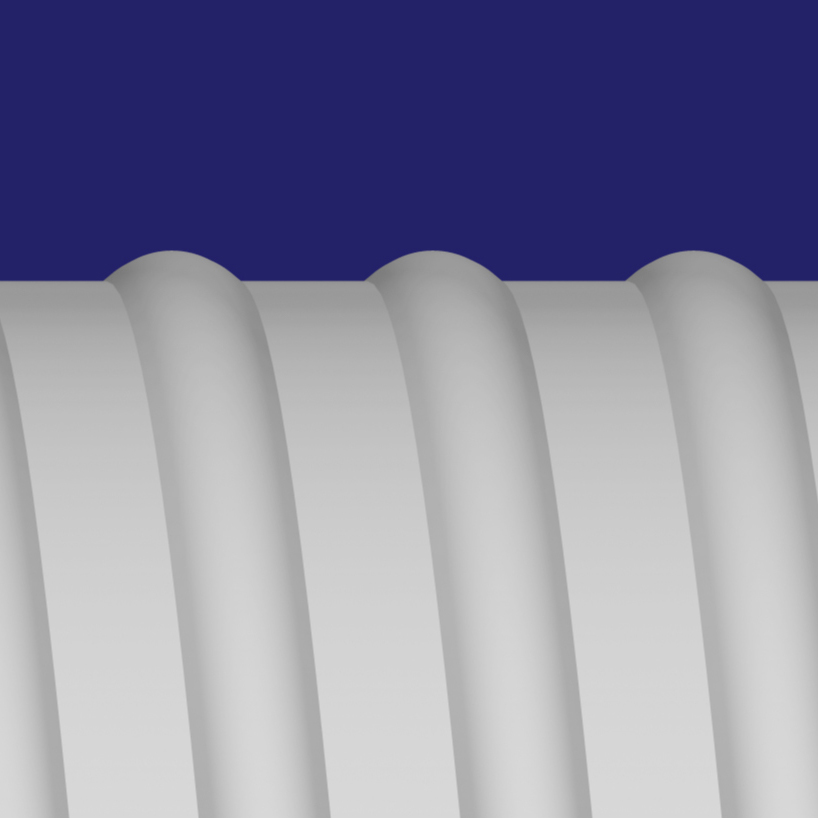

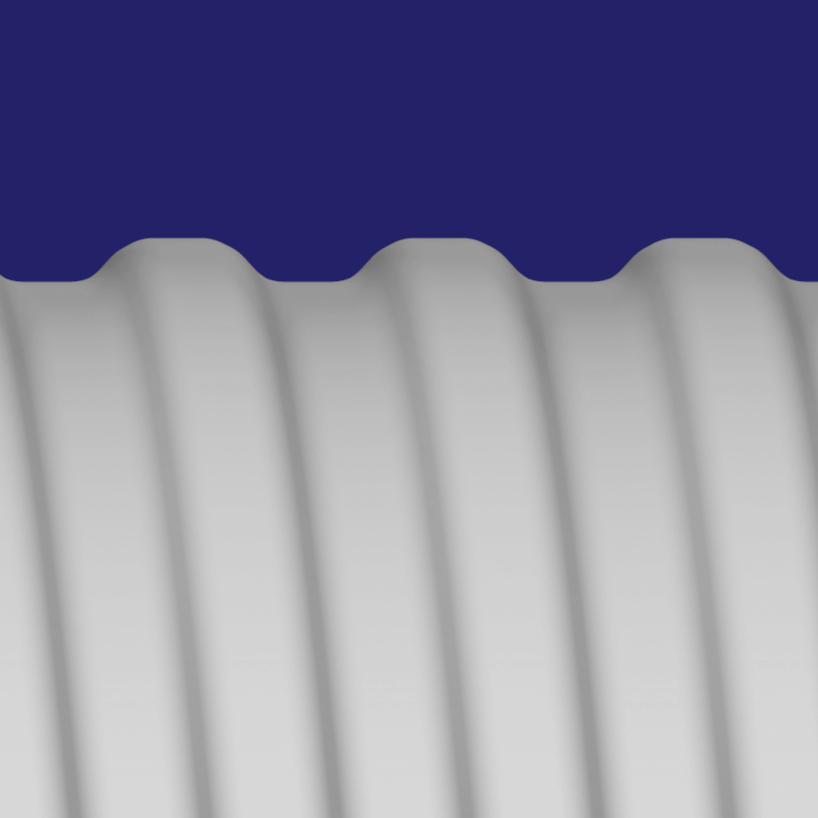

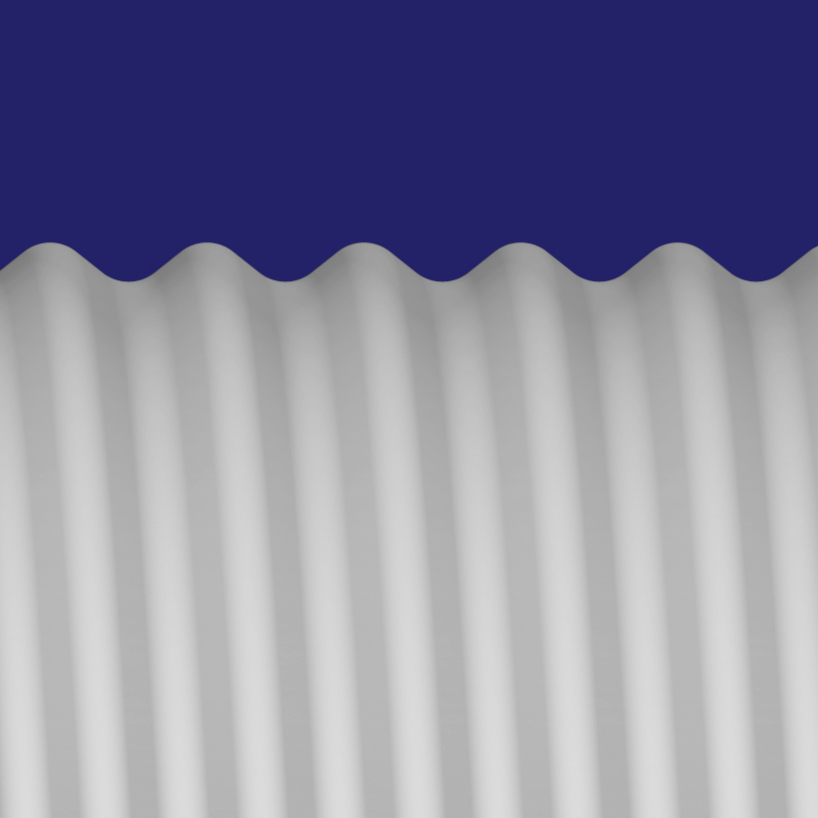

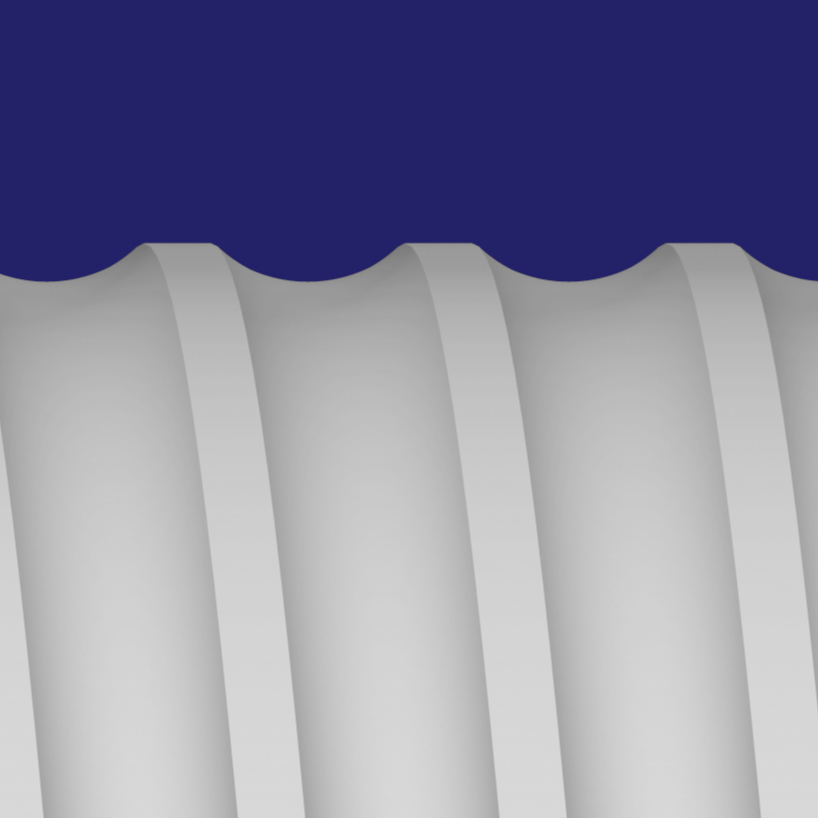

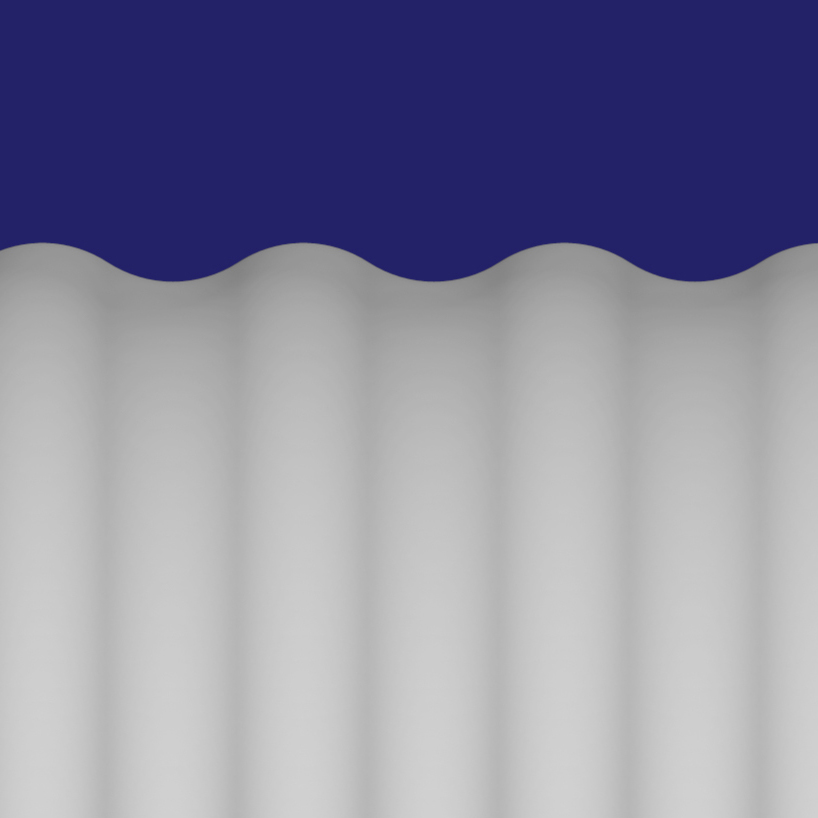

Groove shape lineup and features

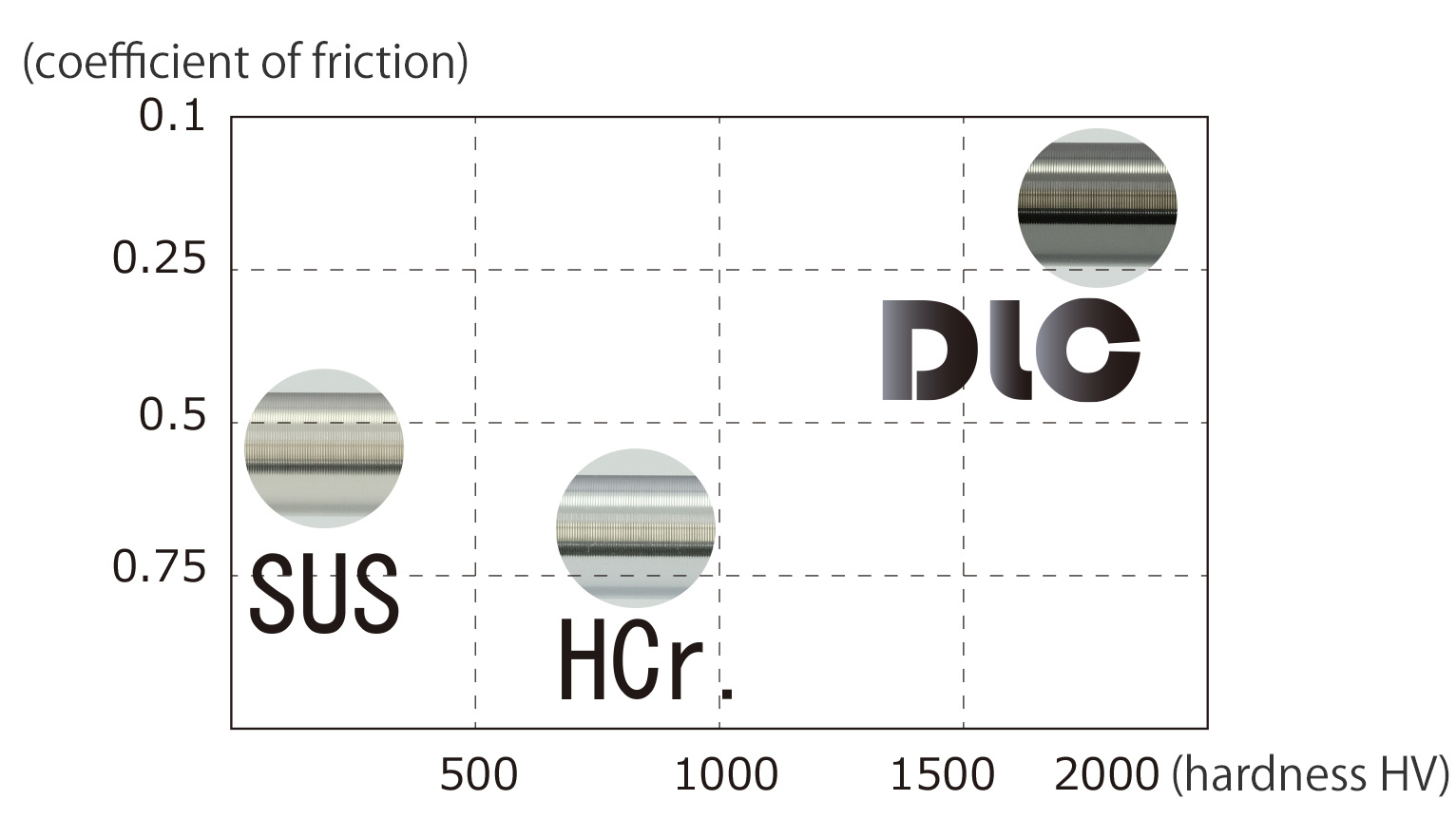

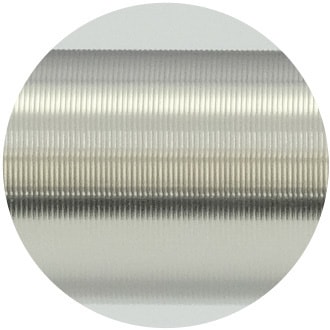

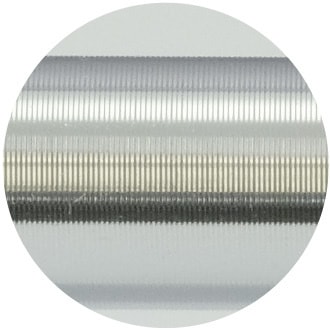

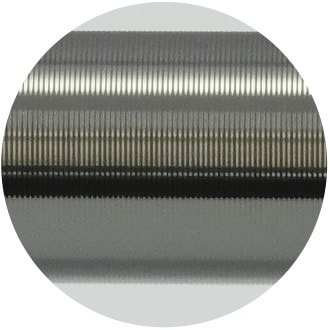

Features of surface treatment

|

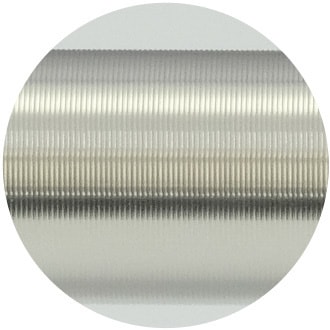

SUSMaterial of D-Bar Use SUS300 series stainless steels(austenitic stainless steel) with good corrosion resistance. |

|---|---|

|

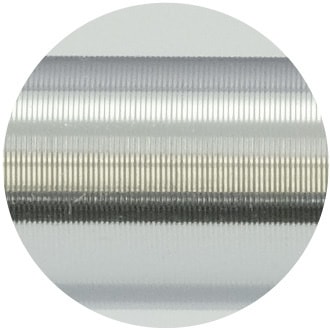

HCr.HCr layer is relatively hard and has excellent abrasion resistance, and corrosion resistance. |

|

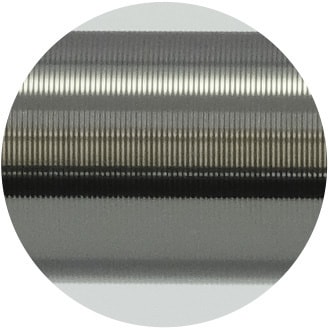

DLCDLC layer is extremely hard and also low in coefficient of friction. In addition, DLC has a higher hydrophilic compared to SUS and HCr plate. |

|

SUSMaterial of D-Bar Use SUS300 series stainless steels(austenitic stainless steel) with good corrosion resistance. |

|---|

|

HCr.HCr layer is relatively hard and has excellent abrasion resistance, and corrosion resistance. |

|---|

|

DLCDLC layer is extremely hard and also low in coefficient of friction. In addition, DLC has a higher hydrophilic compared to SUS and HCr plate. |

|---|

Common consultations and problem-solving examples

We also have solutions for other coating defects such as film scratches, foreign matter contamination, liquid flowing over the edge of film. Besides, we can also help customers saving the liquid, increasing the coating speed and so on.

Please feel free to contact us.