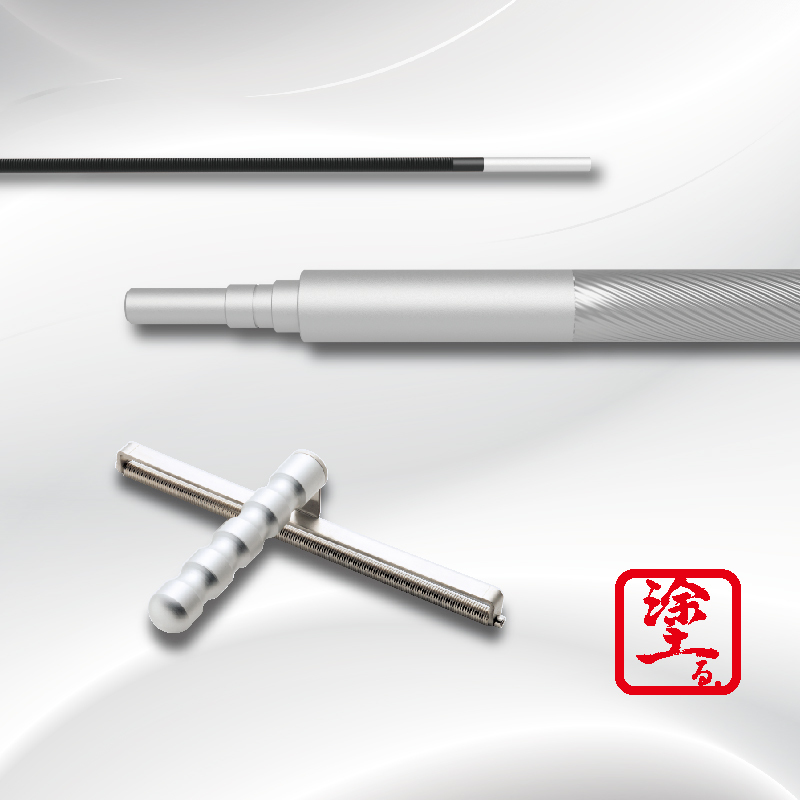

About D-Bar

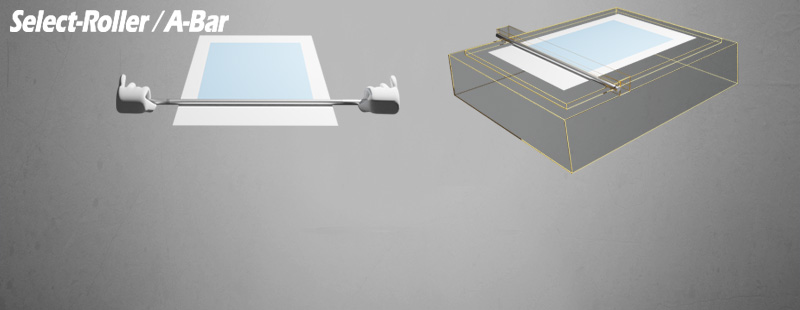

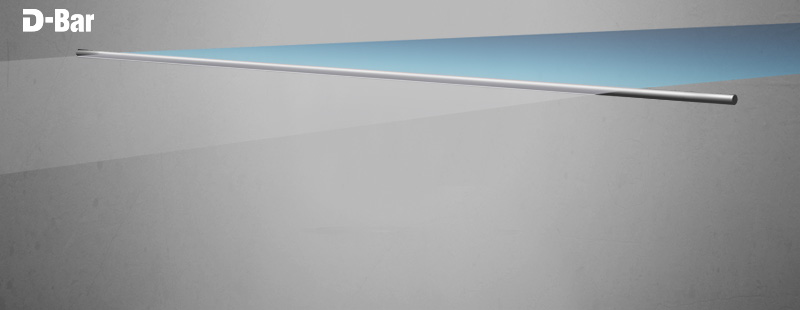

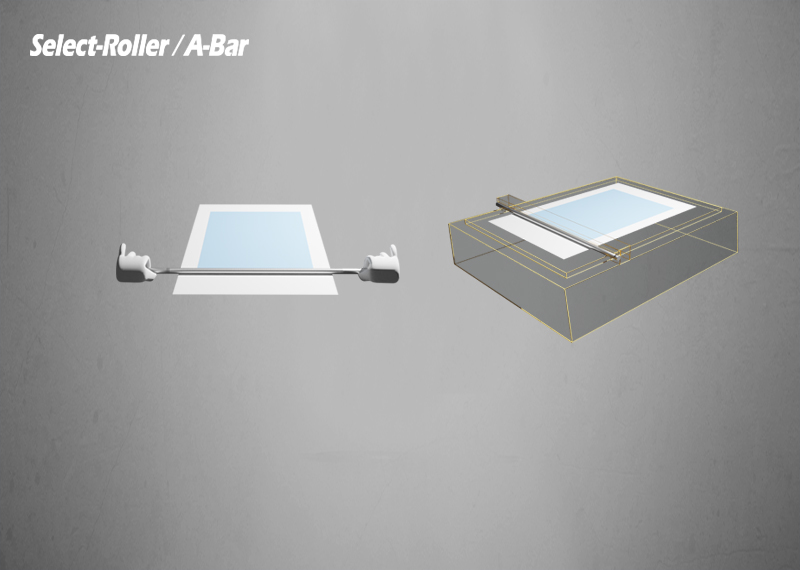

What is D-Bar (E-Roll/Select-Roller/A-Bar)

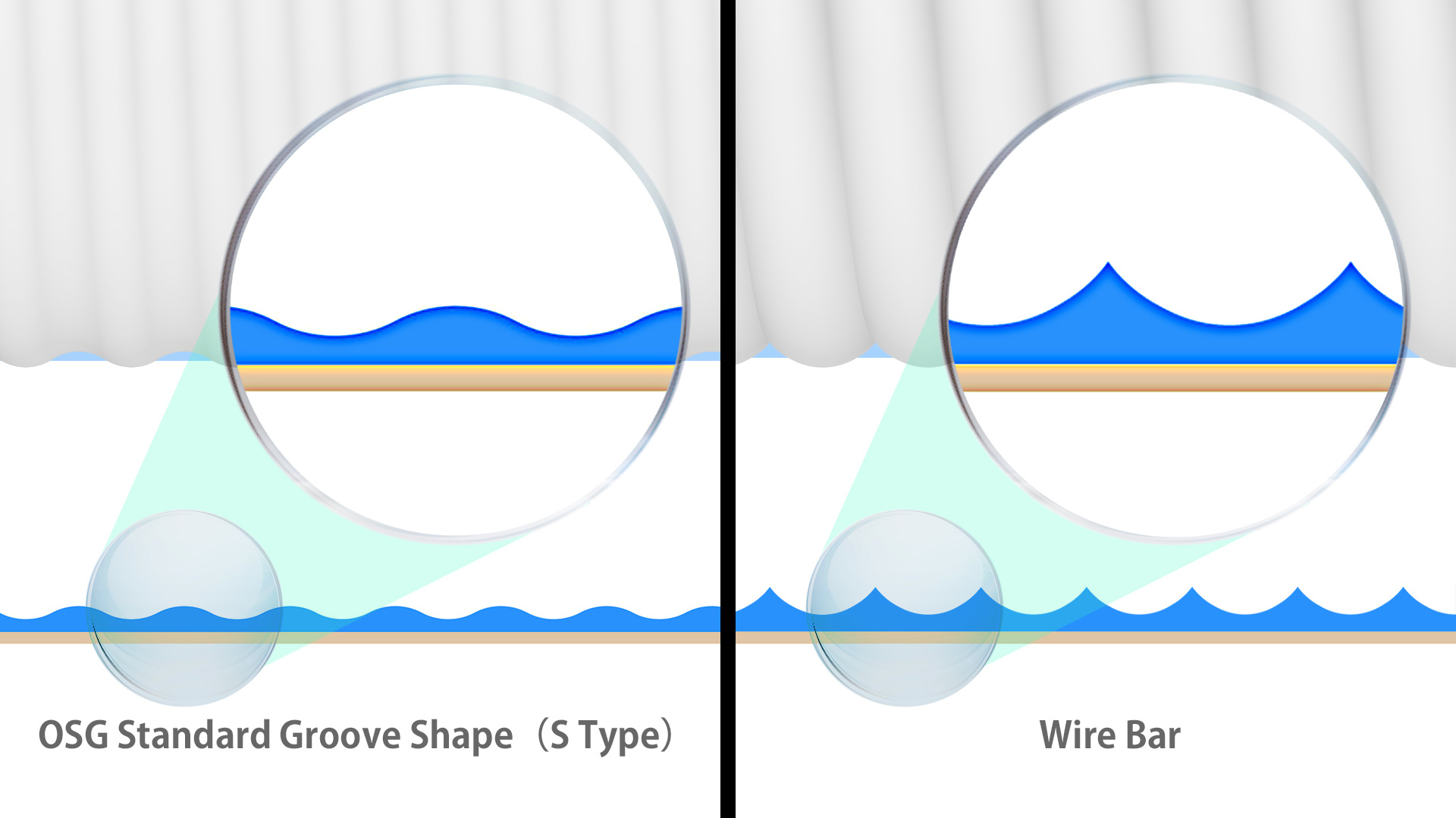

D-Bar is the OSG product with high precision and high efficiency based on the solid technology that has supported the world-wide manufacturing for years. We improved the traditional wire-bar (a kind of coating bar which wire wounded around a core bar) that is widely used in the coating industry. It was commercialized using a manufacturing method that transfers the shape of the mold to the material with high precision using the precision mold technology that OSG has built for many years.

The development of D-Bar started from 1985, and now there are more than 500 kinds of groove shapes (molds) are available. These years, customers from film, special paper, paper, glass and other industries strongly requires for better coating performance such as precise thickness control and multi-layer coating. So D-Bar has been adopted by many customers because of the unique advantages over traditional wire bar.

Features of D-Bar

Feature 1

Free from wire cut or wire displacement.

The bottom of the groove is designed into a wide shape, so the clogging caused by the coating is reduced, and the bar is easier to clean. Long-term and stable coating performance can be expected to achieve.

Feature 2

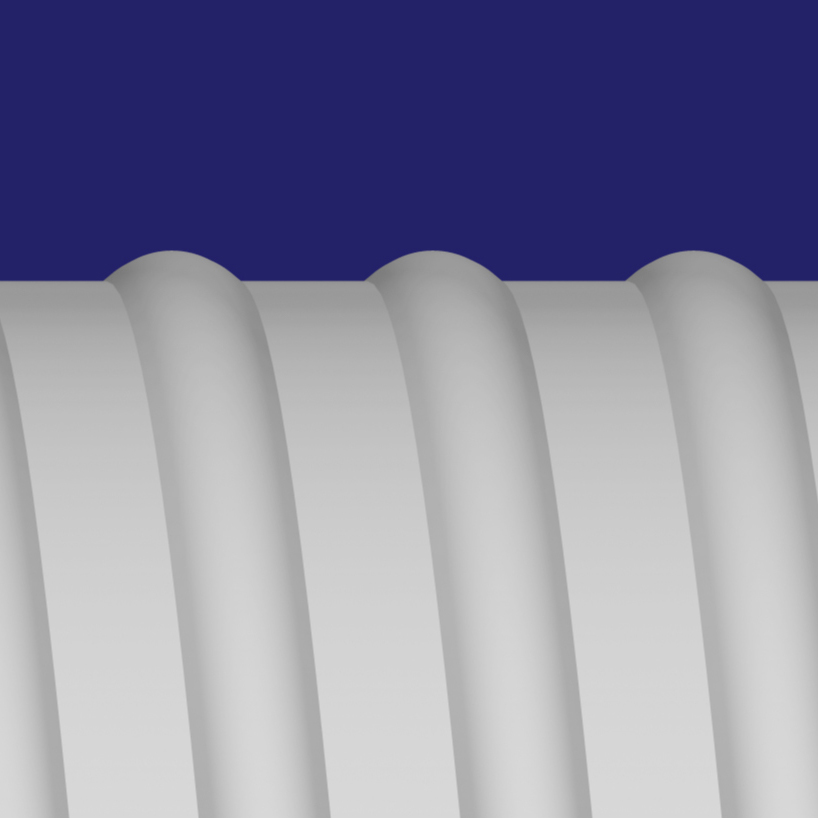

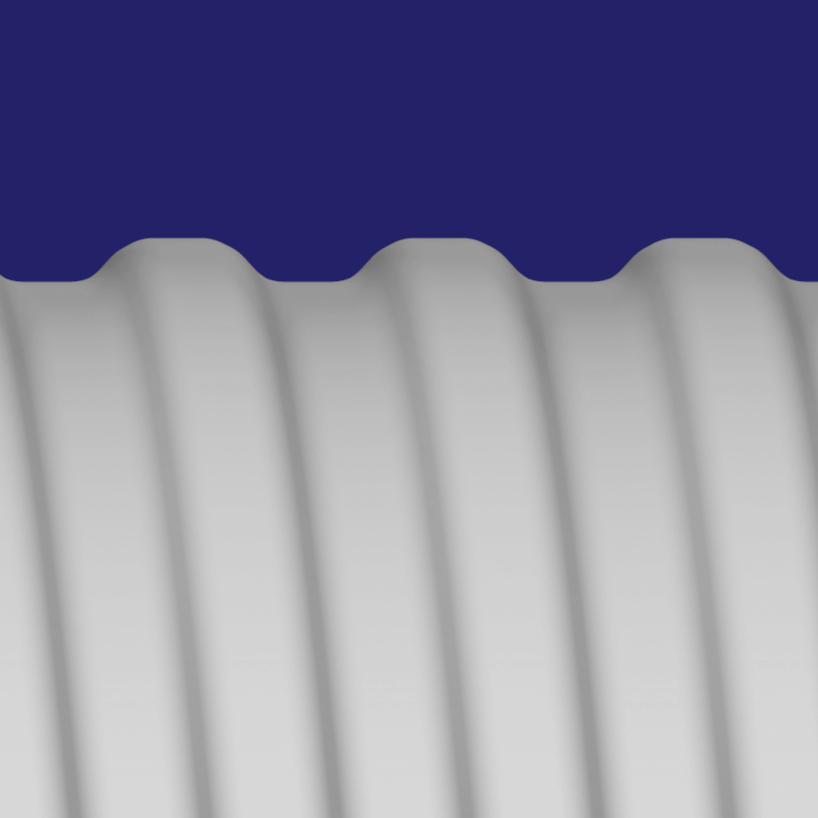

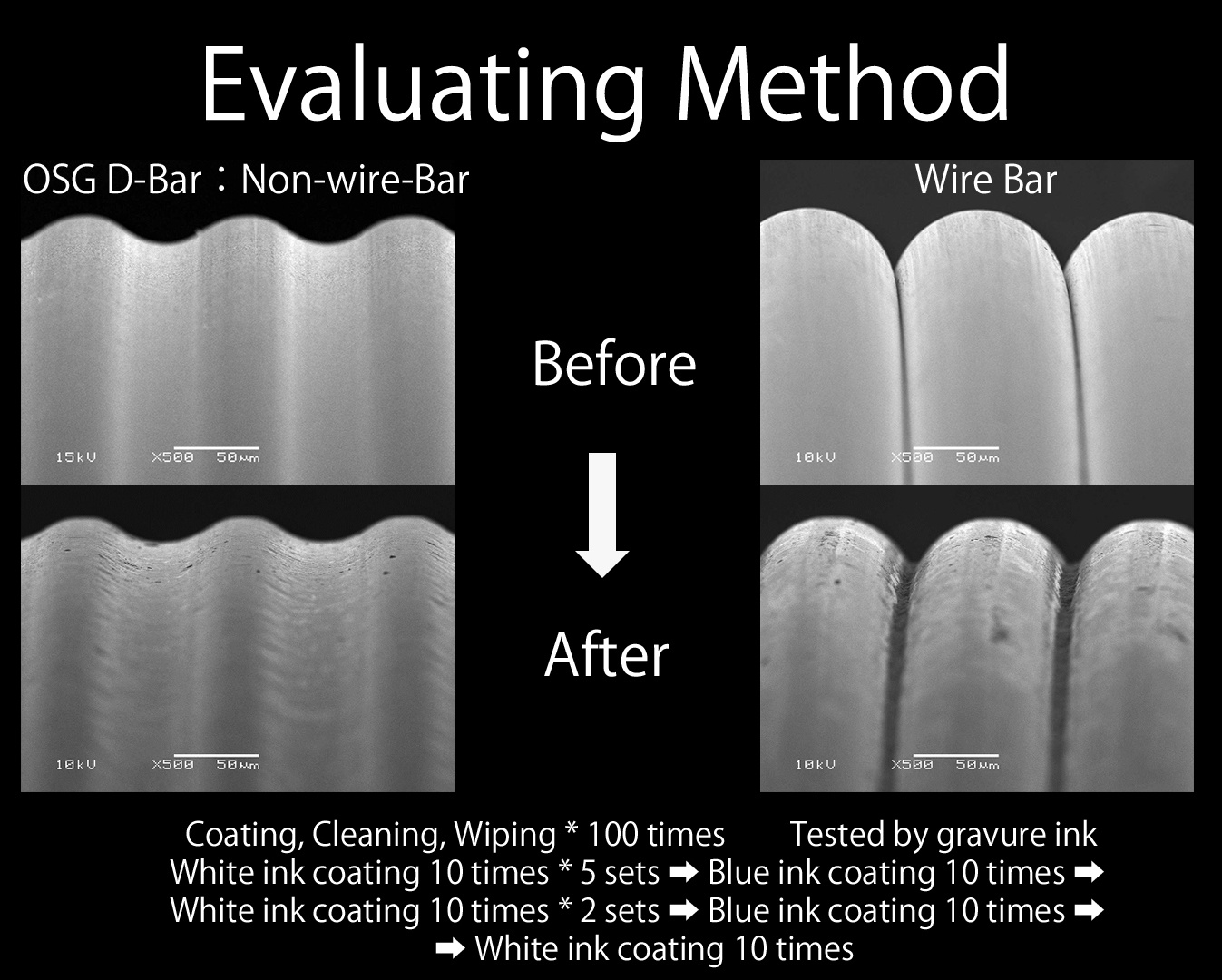

Less clogging and easy to clean.

The bottom of the groove is designed into a wide shape, so the clogging caused by the coating is reduced, and the bar is easier to clean. Long-term and stable coating performance can be expected to achieve.

Test method: Test with ink. (gravure ink)

Coating, Cleaning, Wiping * 100 times

SEM (Scanning electron microscope) Comparison image

Feature 3

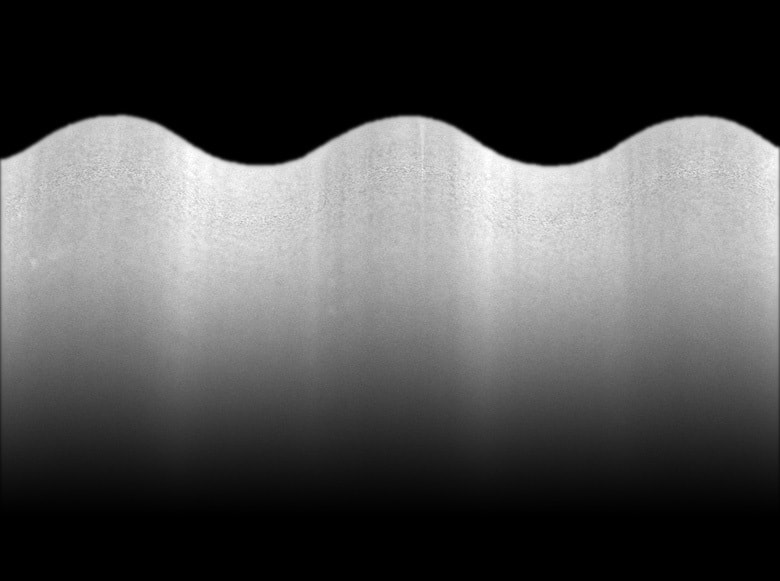

Excellent coating liquid leveling property.

The bottom of the groove is designed into a wide shape, so the coating leveling(smoothing) is excellent. Coating defects such as streaks and stains would reduce and the coating surface quality would be expected to improve.

Feature 4

a wide variety of groove shapes are available.

A wide variety of groove shapes would help improve the coating surface quality.