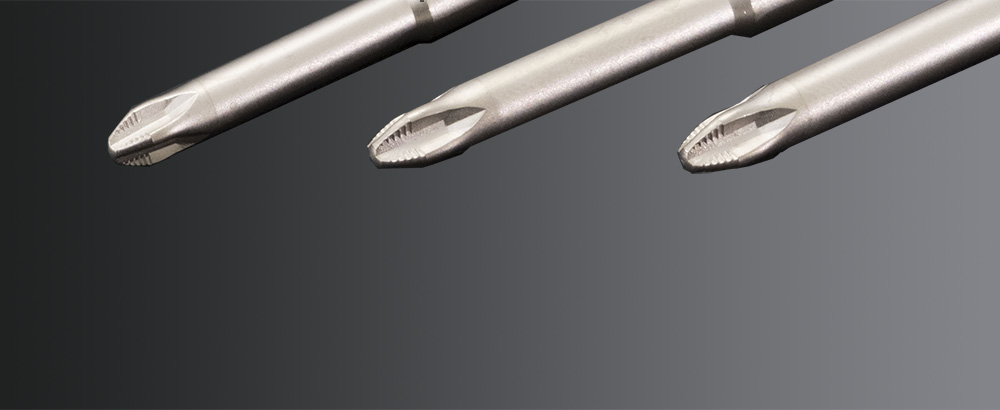

Features of OSG Bits

Unique press forming process developed by OSG produces precision and consistent forms every time creating much stronger concentration of fiber flow our power bits. As a result, quality consistency becomes the standard of OSG power bits that delivers precision tooling with hardness, consistency and maximum torsion strength meeting the market needs. In addition, we can respond your request quickly and flexibly. Please feel free to contact us if you have any questions.

FIBER FLOW

OSG BITS

General milled bits

High precision

OSG bits are manufactured using precision molds in a high-rigidity pressing machine. This process minimizes dimensional variation between each lot i.e. four flute dimentions and grooves.

High precision

OSG bits are manufactured using precision molds in a high-rigidity pressing machine. This process minimizes dimensional variation between each lot i.e. four flute dimentions and grooves.

Torsional strength

Combination of premium material, unique forming process and special heat treatment technology delivers OSG power bits that is guaranteed to maximize your torque transmission.

Torsional strength

Combination of premium material, unique forming process and special heat treatment technology delivers OSG power bits that is guaranteed to maximize your torque transmission.

Features of ACR Bits

No cam-out cross recess bits

Prevents the bits from lifting

Reduce the troubles caused by recess collapsing.

One of the reason of recess collapsing is "cam-out" which means the bits lift from the recess when fastening the screw. ACR BITS prevents the bits from lifiting and improve your workability.

※ACR® is a registered trademark of Phillips Screw Co. of USA.

One of the reason of recess collapsing is "cam-out" which means the bits lift from the recess when fastening the screw. ACR BITS prevents the bits from lifiting and improve your workability.

※ACR® is a registered trademark of Phillips Screw Co. of USA.

Customized Bits

Unique press forming process developed by OSG produces precision and consistent forms every time creating much stronger concentration of fiber flow our power bits. As a result, quality consistency becomes the standard of OSG power bits that delivers precision tooling with hardness, consistency and maximum torsion strength meeting the market needs. In addition, we can respond your request quickly and flexibly. Please feel free to contact us if you have any questions.

Catalog

Unique press forming process developed by OSG produces precision and consistent forms every time creating much stronger concentration of fiber flow our power bits. As a result, quality consistency becomes the standard of OSG power bits that delivers precision tooling with hardness, consistency and maximum torsion strength meeting the market needs. In addition, we can respond your request quickly and flexibly. Please feel free to contact us if you have any questions.

Catalog

Features

- Stability

- Fitting

- Precise dimencional distribution

- Best managed heat treatment

- Most advanced material selection

- Long durability

- Strong fastening

- High breakage resistance

Point type

- Cross recess

- Z-type cross recess

- ACR®

- Slotted

- Hexagon

- Square

- Hexalobular

- Hexalobular

with hole for tamper proof - LHS

Shank type

- Hex 6.35mm (U6.3, V6.3, C6.3)

- U5

- H4

- H5

- D4

- N3

- Double end

- Other (for automation)

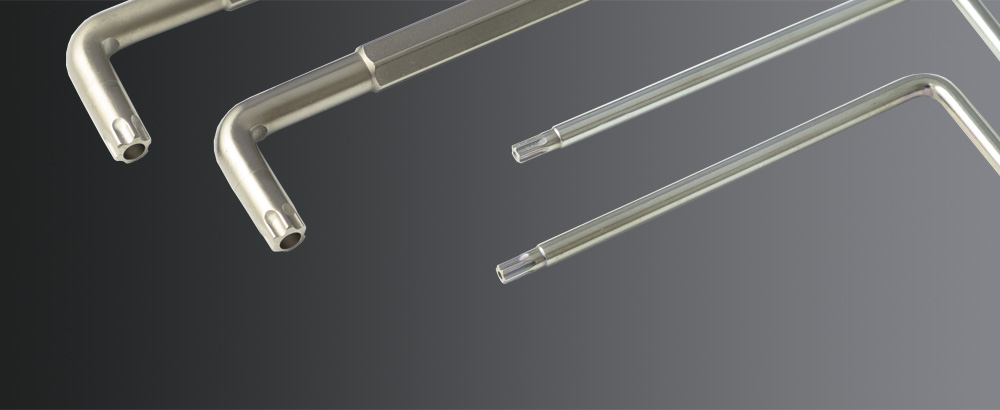

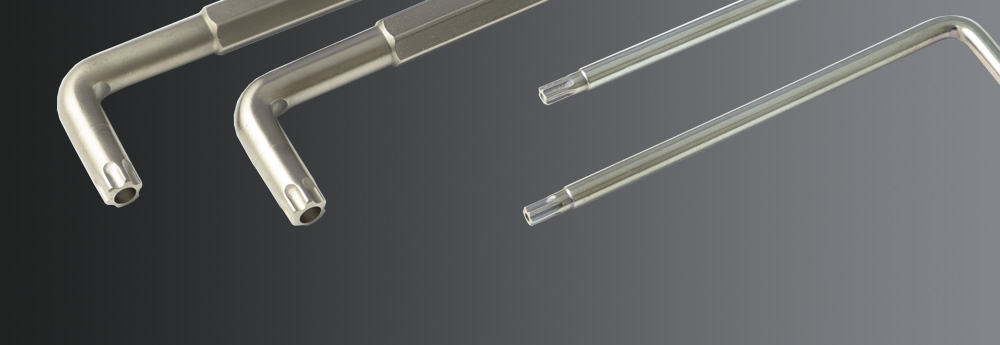

LHSTIX Fastening Tool

LHSTIX screw concept is the result of effort to find maximum efficiency and balance in fastening. Two types of design are 1) Line Recess (LR) having the area of torque transmission in the recessed area of a screw head and 2) Line Head (LH) having the area of torque transmission on the outer circumference of a screw head.

In addition, special features described below are available specifically to your need.

A): LH and LR include specific tapered angle between the driving tool and screw head design.

B): LH-S, LH-SS, LR-S, LS, and LX does not have specific tapered angle between the driving tool and screw head design.

C): ULR, Ultra Line Recess, for the miniature screw group and Rock star for construction screw.

D): LR-T, 5LR, 3ULR, and 5ULR have a security screw functions.

E): LS and LX recess possible to use standard tools

Also we have newly added for lineup our original cross recess (QuaStix)

Catalog

LHSTIX screw concept is the result of effort to find maximum efficiency and balance in fastening. Two types of design are 1) Line Recess (LR) having the area of torque transmission in the recessed area of a screw head and 2) Line Head (LH) having the area of torque transmission on the outer circumference of a screw head.

In addition, special features described below are available specifically to your need.

A): LH and LR include specific tapered angle between the driving tool and screw head design.

B): LH-S, LH-SS, LR-S, LS, and LX does not have specific tapered angle between the driving tool and screw head design.

C): ULR, Ultra Line Recess, for the miniature screw group and Rock star for construction screw.

D): LR-T, 5LR, 3ULR, and 5ULR have a security screw functions.

E): LS and LX recess possible to use standard tools

Also we have newly added for lineup our original cross recess (QuaStix)

Catalog